Pushing Your NC Miata Further: Advanced Performance Upgrade Guide

For Miata owners moving beyond basic mods, forged internals (pistons, rods, crank) are essential for boosted or high-rev builds. Pair them with ported heads, upgraded valvetrain, and performance cams for reliable high-output performance.

More horsepower means more heat, greater strain on the drivetrain, and new handling dynamics that can surprise you if not addressed. The target audience for this sequel is the enthusiast who has already tackled basic mods and wants to take the next logical step. Still, new Miata owners might benefit from reading about what lies ahead, even if they’re still finishing the initial upgrades.

Engine Internals and Reinforcements

When your performance ambitions exceed the limitations of bolt-on modifications, upgrading engine internals becomes more than just a luxury, it is almost mandatory. Pistons, rods, and crank components handle intense cylinder pressures, especially in high-compression or boosted setups, and stock cast parts can fail under these conditions. Forged pistons and rods, in particular, have grains aligned in a way that enhances their tensile strength, reducing the likelihood of fracture or bending. If you plan on forced induction or an aggressive high-rev build, moving to forged internals is a strong safeguard against engine knock, ring damage, and rod failure.

Cylinder head work also plays a significant role in performance at elevated power levels. Porting and polishing enlarge and shape the intake and exhaust ports to help airflow, while smoothing the surfaces decreases turbulence. Upgraded valves, valve springs, and titanium retainers can enable higher RPM ranges without risking valve float. In tandem with forged internals, a more free-flowing cylinder head can yield a powerful engine that still offers reliability. Performance camshafts, too, can shift the powerband upward, but they usually require detailed ECU tuning to maintain a workable idle and deliver proper fueling. Taken together, these internal reinforcements and head enhancements ensure that your Miata’s engine stays intact while delivering more substantial gains than bolt-ons alone can offer.

Forced Induction

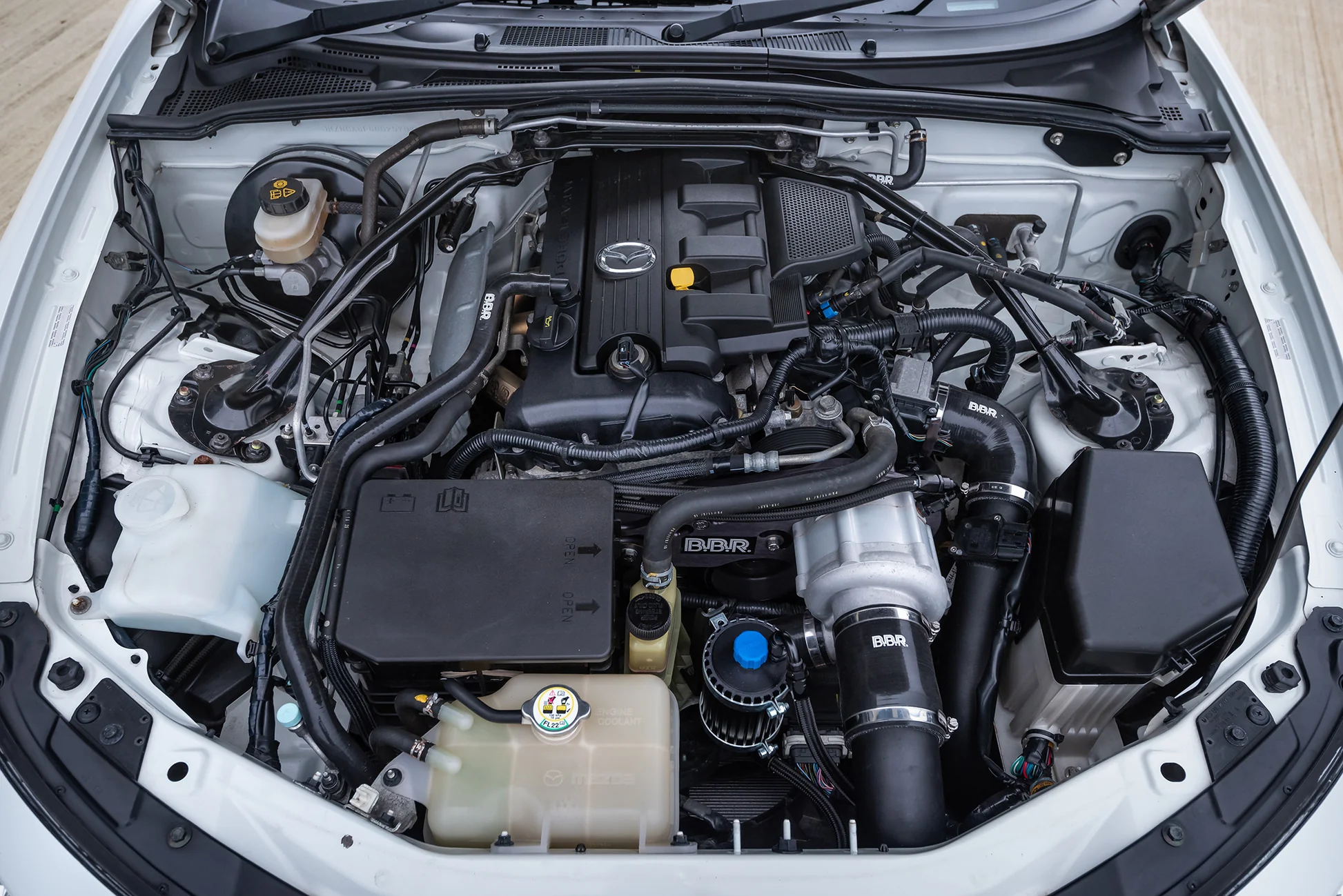

While naturally aspirated setups can produce respectable gains, forced induction generally delivers a larger jump in horsepower and torque. However, it also brings more complex tuning requirements and heat management challenges. Turbocharging and supercharging differ in power delivery, drivability, and installation needs. A turbocharger uses exhaust gases to spin a turbine, compressing more air into the engine. Smaller turbos spool quickly but limit high-end power, whereas larger ones produce bigger peaks but may lag in the low RPM range. Superchargers, in contrast, can be either positive displacement units that provide immediate low-end torque or centrifugal designs that mimic the power curve of a turbo by building boost with engine speed.

Whatever your choice, turbo or supercharger, you must consider manifolds, intercoolers, and oil/coolant lines. A carefully sized manifold channels exhaust pulses effectively and prevents heat soak in the NC’s relatively tight engine bay. Intercoolers or aftercoolers keep intake temperatures manageable, preventing knock and power loss. Oil and coolant lines must be routed and pressurized correctly, as forced induction setups punish lubrication and cooling systems much harder than stock conditions. Tuning becomes critical in this environment because mismatched ignition timing and fuel trims can quickly lead to engine meltdown. Experienced tuners often incorporate safety nets like boost cuts and knock detection maps to minimize risks. Forced induction can be transformative, but it demands robust supporting hardware and meticulous calibration.

Fuel System Overhaul

Whether you remain naturally aspirated with aggressive internals or decide on forced induction, you’ll almost certainly need to upgrade your fuel system. Stock injectors and pumps often prove inadequate once you push beyond modest power levels. High-flow injectors provide the additional fuel required, and a stronger fuel pump prevents pressure drops during wide-open throttle. E85 introduces another layer of possibility, thanks to its higher resistance to knock and capacity for more advanced ignition timing. It does, however, require about 20–30% more fuel flow and hardware that’s compatible with ethanol. Flex-fuel sensors can let the ECU automatically adjust fueling and timing based on how much ethanol content is in the tank.

After you increase injectors and upgrade the pump, you might need an adjustable fuel pressure regulator to maintain stable pressures. Fuel pressure logs will reveal if you’re experiencing sudden drops under load. In short, a well-thought-out fuel system is essential for any high-power build, especially once you introduce high compression or increased boost.

Supporting Systems and Cooling

Increased horsepower output naturally creates more heat. Stock radiators and cooling fans can struggle with the thermal demands of advanced builds, especially on track days. Aluminum radiators with dual-pass or triple-pass designs enhance heat dissipation by allowing the coolant more contact time. An oil cooler is also wise for spirited driving or competition settings, as oil temperatures can rise quickly under heavy throttle and high RPM, threatening lubrication quality.

Proper airflow management goes beyond just the radiator itself. Fan shrouds, hood vents, and ducting are all critical to ensuring cool air moves efficiently through the radiator rather than around it. Supercharged or turbocharged engines should incorporate an intercooler (or aftercooler) to reduce charge-air temperatures, a step that directly helps in controlling knock and improving consistency. These measures collectively help you extract maximum performance without thermal issues cutting your sessions short.

Suspension Tuning and Chassis Reinforcement

A big performance jump in the engine bay won’t be fully realized if your suspension and chassis lag behind. Coilovers are a central feature of advanced suspension setups, allowing you to tailor spring rates, adjust damping, and fine-tune ride height to balance daily comfort and track performance. Sway bars and end links should be selected carefully: a thicker sway bar reduces body roll but can change the car’s balance between understeer and oversteer. Adjusting end links can help dial out any unwanted preload and achieve more precise cornering behavior.

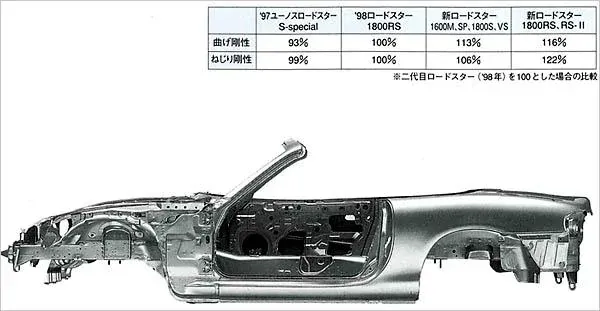

Chassis stiffening measures also become significant as power and cornering forces climb. Components like strut tower braces, frame rail reinforcements, and a roll bar can collectively reduce flex. Not only does this firm up handling, but it also increases safety. Finally, consider upgrading the car’s bushings from soft rubber to stiffer polyurethane or spherical bearings to tighten steering response. The trade-off is that you may notice more noise and harshness, a key consideration for street-driven cars.

Brakes and Stopping Power

All the power in the world won’t help if you can’t stop effectively. Upgraded pads with higher temperature tolerances, along with quality rotors (be they slotted, drilled, or blank), form the first layer of a more robust brake system. Big Brake Kits (BBKs) expand on this with multi-piston calipers that distribute clamping force evenly and dissipate heat faster. Keep an eye on caliper dimensions, however, as larger units sometimes require specific wheel sizes for clearance.

High-temperature brake fluid, such as DOT 4 or DOT 5.1, resists boiling better under the repeated heavy braking you’re likely to encounter with a significantly faster Miata. Stainless-steel lines reduce flex, improving pedal feel under load. For extended track outings, brake ducts help channel cool air directly to the rotors, preventing fade and extending pad life. The main point to remember is that as horsepower and speed ramp up, your braking system needs to evolve just as aggressively.

Aerodynamics and Weight Management

When speeds rise, aerodynamics and weight management become serious considerations. Aerodynamic modifications like front lips or splitters reduce front-end lift, improving stability at highway and track velocities. Spoilers or wings at the rear can plant the back end, especially if they’re well designed for the Miata’s shape. A diffuser keeps airflow smooth underneath the car, creating a measure of downforce without excessive drag.

Removing weight boosts performance in nearly every category, from acceleration and braking to cornering agility. Simple strategies like installing lightweight wheels or swapping out heavy seats can make a noticeable difference. At the extreme end, carbon fiber or fiberglass body panels cut pounds drastically, though they can be expensive and sometimes have fitment challenges. Ultimately, you want to balance weight savings with usability, gutting the interior for track days might compromise daily comfort, so choose carefully based on your goals.

Advanced Tuning and Data Analysis

As you move into more advanced build stages, especially with forced induction or high-compression internals, you can’t rely on preset tuning solutions. Data logging becomes essential to understand how your engine handles ignition timing, boost, air-fuel ratios, and potential knock events. You can collect data via OBD2 loggers or more specialized tools. This information guides incremental tuning adjustments, ensuring you don’t push into dangerous territory.

Some Miata owners will maintain separate ECU maps for different uses. One might be a street map with less aggressive timing for daily commuting, while another could be a “track map” designed to handle extreme heat and extended wide-open-throttle runs. Both dyno and road tuning have their merits: dynos provide controlled conditions and exact power figures, while road tuning captures real-world load and weather variables. If there’s no specialized tuner nearby, remote tuning with frequent data-logging uploads is an option, albeit one that requires diligence to confirm engine safety.

Maintenance, Reliability, and Longevity

High-performance parts demand a more thorough maintenance regimen. Spark plugs, belts, and hoses should be inspected more frequently. Pay attention to fluid conditions, as heavy load can degrade oil or brake fluid faster than in stock cars. Synthetic oils and higher-temp brake fluids are often necessary. It’s also wise to perform periodic compression or leak-down tests, particularly if you have a forced-induction build that is prone to greater stress.

Realistic power targets remain crucial. Even a well-built engine has practical limits. Pushing beyond safe power margins without the right internals or tuning strategies can lead to catastrophic failure. A phase-by-phase strategy, test and refine each step before chasing bigger numbers, helps you avoid expensive pitfalls and ensures each modification works in harmony with the rest of the build.

Putting It All Together

A logical progression for advanced builds typically starts with improving cooling and fueling systems, followed by reinforcing the engine internals once you decide on substantial power gains. Only then should you add turbochargers or superchargers, along with a tune specifically crafted for your setup. While you’re increasing power, address suspension, chassis stiffness, and braking to create a more cohesive and safer high-performance vehicle. Aerodynamic tweaks and weight-saving measures round out the build, helping you maximize the Miata’s potential on both road and track.

For further inspiration, look to case studies of NC Miata owners who successfully combined forced induction and chassis upgrades. Their stories often highlight the nuances of managing heat, maintaining reliability, and calibrating multi-map ECUs for different scenarios. If you find yourself ready for a deep dive into track setups, investigate more specialized topics like custom alignment specs or corner weighting, which can eke out even more speed and control.