Going Carbon-Fiber? Wrap vs. True Composite Panels on Your Miata

Chasing Miata rattles? Make the noise repeat first—30–40 km/h ripples, light throttle, roof latched/unlatched. Change one variable at a time, strip cargo, tape-test seams, finger-preload trim. Stock up on felt, Tesa tape, foam, silicone spray, PTFE lube, and fresh clips—OEM buzz-fix essentials

(buyers’ guide: look, weight, safety, longevity, and $/kg reality)

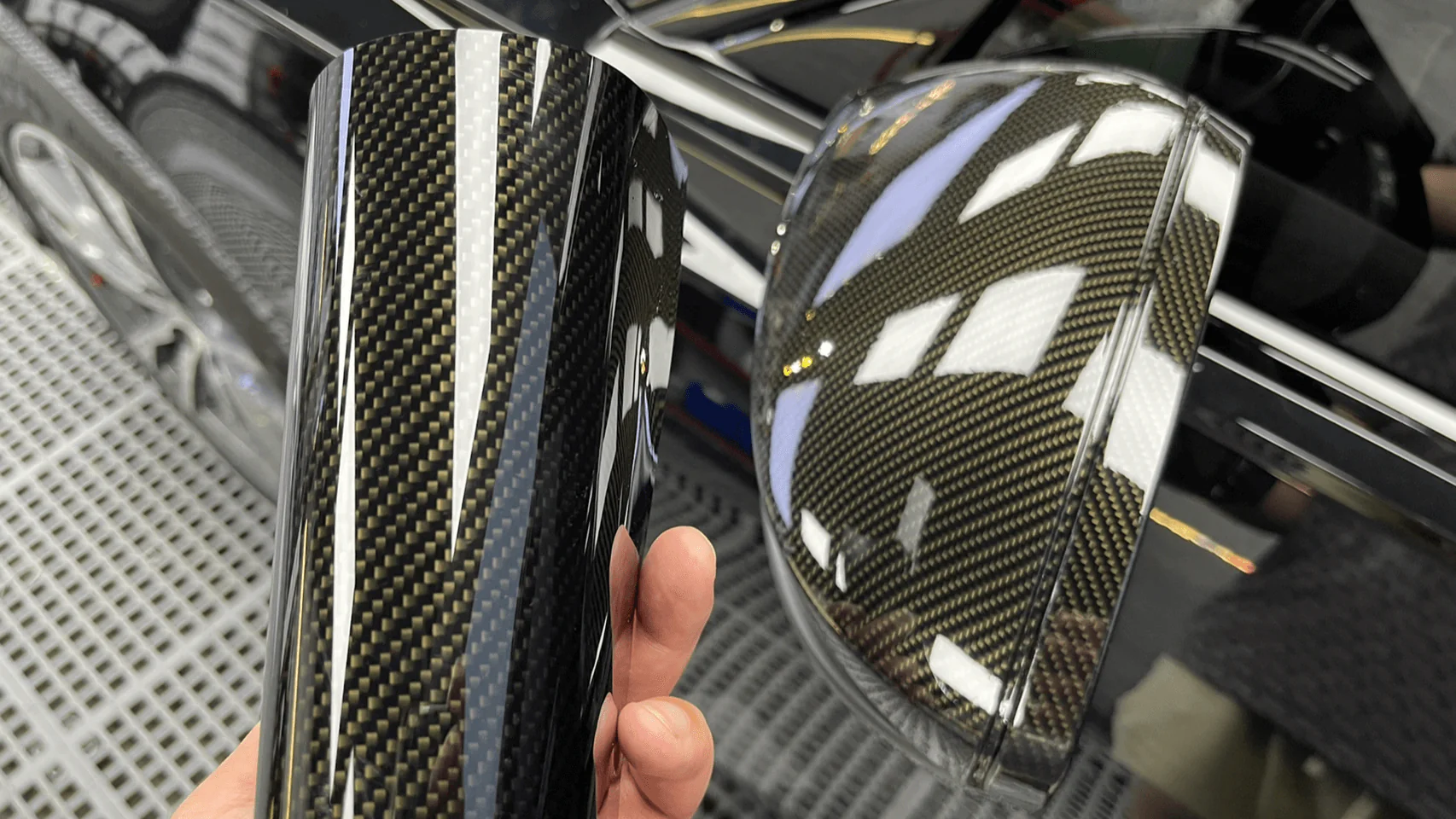

When people say “carbon,” they usually mean one of three things. First is carbon-look vinyl wrap, which is simply a cosmetic film over your paint. It protects the finish from light scuffs and adds essentially no weight. Modern premium films publish durability by climate and by whether the surface is vertical or horizontal, and they expect proper edge post-heating to “lock” the film. Second is a carbon-fiber reinforced plastic (CFRP) body panel made by wet layup or vacuum infusion. That’s carbon fabric soaked with resin and cured in a mold; quality depends on how well the fabric is consolidated and how much extra resin is trapped. Infusion and vacuum bagging reduce voids and produce stronger, lighter parts than a simple hand layup. Third is pre-preg, often called “dry carbon.” The resin is factory-metered into the fabric, then cured with heat and pressure, often in an autoclave. This delivers the highest fiber volume, lowest voids, and the cleanest out-of-mold finish, usually the lightest and stiffest option.

Looks vs. Mass vs. Function

If you want the look and some paint protection, wrap is the smart play. Film thickness is only fractions of a millimeter, and on vertical surfaces in mild climates these films can last many years when installed correctly. If you’re chasing real weight savings, vents, or heat extraction, you need composite panels. The process and layup determine whether you end up “similar to stock” or dramatically lighter. Vented hoods and lightweight hardtops also change airflow and under-hood temps, things a wrap can’t do.

Have an ND? gains can be small

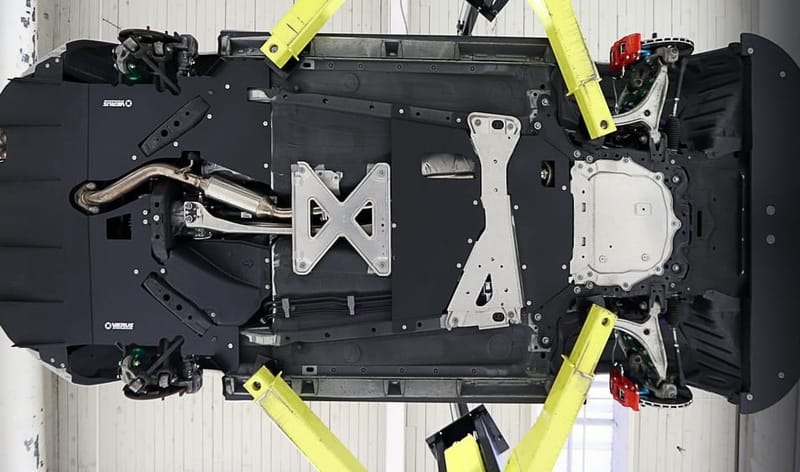

Miatas differ a lot by generation. The NA already came with an aluminum hood, so you’re not starting from heavy steel there. The NB’s stock hood is commonly reported around the mid-teens in pounds, which makes it a handy target for savings. The NC’s steel shell makes aftermarket composite hoods and hardtops attractive for mass reduction. The ND leaves the factory with aluminum hood, trunk lid, and front fenders, which means the hood delta is small unless you go full-tilt carbon; you’ll often find better returns in the trunk, fenders, or a lightweight top.

Numbers vary by manufacturer and exact construction, so always confirm stated weights. “CFRP skin over a fiberglass core” is not the same as full carbon. On the ND, the OEM hood is roughly nine to nine-and-a-half kilos; many “OEM-style CFRP” hoods also land around nine kilos (no meaningful savings), while true full-carbon hoods can be closer to six. On older cars, a dry-carbon NA hood can drop several kilos versus stock, and even budget fiberglass race hoods can land around the single-digit pounds, great dollars-per-kilo, though they require finish work. Trunks across NA, NB, and ND can deliver multi-kilogram savings with full carbon, while hybrid constructions may be much closer to stock. Doors can save a lot of weight with full shells, but you trade away side-impact structure and weather sealing, so they’re typically a track-only move. For tops, an NA/NB fiberglass race hardtop near fifteen pounds (no glass or seals) is a massive aero and rigidity win. ND carbon “street” tops are often less than half the mass of OEM but bring more noise and less perfect sealing, set expectations.

why two “carbon” hoods may feel different

Open-mold hand layups are the easiest and cheapest to produce, but they’re usually resin-rich, heavier, and can show print-through and surface waves. Vacuum-bagged wet layups and vacuum infusion improve consolidation and reduce voids, producing stronger, lighter laminates when parameters are dialed. Pre-preg parts go a step further: tightly controlled resin content, debulk cycles, and higher cure pressures yield very low voids, excellent stiffness-to-weight, and a crisp surface right out of the tool. In short, higher fiber fraction and lower voids mean better stiffness and crush resistance; sloppy layups throw away performance.

Wraps: how to install, and how they last

Don’t just ask for “carbon wrap”, spec the exact film line and finish. Reputable lines publish face-film thickness and durability tables by climate and orientation. Installation discipline matters: keep protective caps on gloss films until just before post-heating, use dry application, manage panel temperatures, and post-heat edges and seams to set the film’s memory.

Composites: UV, engine-bay heat, and surface care

UV light doesn’t hurt the carbon fibers; it attacks the epoxy resin that holds them. That’s why clear coats or UV-stable gel coats matter. Over time, daily sun can yellow or cloud the surface, but a sound laminate can be sanded and re-cleared. Under-hood parts live a tougher life: most brands recommend or require heat shielding and secondary latching. Treat those as mandatory if you want longevity and a stress-free inspection.

Track-day Notes

Many carbon hoods need a secondary latch, and most manufacturers insist on hood pins regardless of “OEM latch compatible” marketing. Track inspectors like seeing them, and it’s cheap insurance against flutter or a latch failure. As for class rules, allowances for bodywork, venting, and hood fasteners vary. Always check the latest rulebook for your series or club before you spend.

Chasing the best $/kg

On the ND, go after the trunk, fenders, and especially a lightweight top before you chase the hood; the OEM aluminum hood is already light, so only full carbon or pre-preg versions produce meaningful savings. On NA/NB cars, the hood and trunk are high-impact moves. A budget fiberglass hood can deliver standout dollars-per-kilo, and a lightweight hardtop radically improves aero balance and confidence at speed if you can live with extra noise and harsher sealing.

Installation

For wraps, do a full decon and polish first, then follow the film’s temperature windows. Dry-apply with controlled heat, work in overlapping strokes, and only remove any protective cap right before post-heating. Post-heat all edges and seams and use edge sealer on high-stress lips. For composite panels, dry-fit and shim to get even gaps because open-mold parts often need minor bodywork. Transfer hinges, bump stops, and hardware carefully, align the latch, and install quality hood pins even if the listing says you don’t need them. Add under-hood heat shielding, seal any raw edges, and finish with a UV-stable clear or verify that the gel coat is UV-resistant.

What changes in the real world

Wraps don’t change weight and are all about looks and light protection; they demand proper post-heating and edge management and have climate-dependent durability. Wet/infused CFRP can save from a little to a lot depending on the part and the layup, but expect fitting and finishing. Pre-preg parts offer the best stiffness-to-weight and the cleanest surfaces, but they cost the most. For track use, treat hood pins as non-negotiable no matter which composite you pick.

Buyer notes

On the ND, a listing that says “CFRP with fiberglass structure” and still weighs around nine kilos won’t beat the stock aluminum hood on mass, verify the grams before buying. Look for full-carbon options quoting closer to six kilos if weight is the goal. On NA/NB cars, sub-seven-kilogram “dry carbon” hoods exist and deliver headline savings; even a ten-pound fiberglass hood is a great budget move. For hardtops, NA/NB fiberglass race tops around fifteen pounds are proven performers. ND carbon street tops save real weight but increase noise and reduce sealing quality, make peace with the trade-off. On the ND’s aluminum front fenders and trunk, you’ll need fully carbon parts with published weights to see meaningful deltas.

If you’re considering wraps, stick to reputable lines with published durability tables, respect post-heat, park in the shade when you can, and use mild wash chemicals. Expect shorter life on horizontal panels. For composites, use heat shields under hoods, maintain a UV-stable clear, and budget for occasional re-clear cycles if the car lives outdoors in full sun.

For wraps, ask for the film line and finish code, the production date, the durability table for your climate and panel orientation, your installer’s portfolio, and their post-heat and edge-sealer plan. For composite panels, ask which process was used (open-mold, vacuum-bag, infusion, or pre-preg), the stated weight with tolerances, the layup schedule, UV finish details, hardware and latch compatibility, written confirmation on hood-pin requirements, and the lead time and return policy.