Engine Rebuild Diaries: Bringing Your Miata’s BP Back from the Dead

Engine rebuilds go beyond specs—they’re journeys filled with surprise costs, late-night tuning sessions, and that rewarding first idle at 850 rpm. A rebuild diary captures the real story behind every refreshed BP heart.

Miata owners swear the car is “perfect out of the box,” then gleefully pull its heart out chasing silkier bearings, crisper compression, and that intoxicating first fire-up on break-in oil. A rebuild diary turns a dry spreadsheet into a story packed with real-world budgets, curve-balls, and the quiet joy of an 850-rpm idle.

At a Glance

A basic DIY stock refresh targets ~120 whp for roughly $1,900–$2,600 all-in, with about $1,200 in parts. logging forty hands-on hours and wrapped up in three to four weeks. On the opposite extreme, a pro-built track animal built for 20 psi devours $9,450–$12,900, soaks up ninety shop hours, and can monopolize an entire quarter once machine-shop queues, holidays, and dyno time are factored in. Sitting neatly between is the forged street motor at $4,470–$5,500, stretching the calendar eight to ten weeks. These aren’t guesses; they’re the hard numbers our diarists tracked while chasing that brand-new-engine feel.

Exhibit A

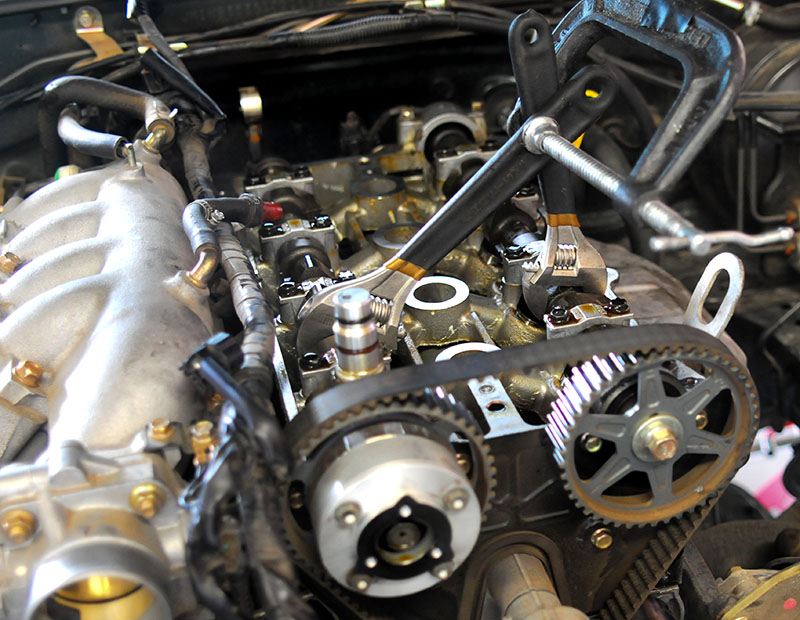

This ’96 NA showed sagging oil pressure and a 10-psi lag on cylinder 3. One Saturday this Miata rolled onto homemade ramps, unbolted the long-block, and six greasy hours later every component was tagged in freezer bags. Two weeks after drop-off, the block and head came back hot-tanked, lightly honed, and with freshened valve seats for $480. This Mazda-heavy shopping cart, OEM gasket set,

water pump, timing kit, upgraded oil-pump gears, bearings, and an Exedy clutch, rang in at $720. Twenty-four late-night hours of plastigauging and ring-filing followed. Three pulled head-bolt threads forced a Timesert kit and another $86, yet the motor barked to life exactly four weeks after tear-down. Aside from a loose heater-hose clamp that turned the firewall into an impromptu fountain, it now purrs, and learning 90 percent of engine-building craft for less than a new set of coilovers.

Exhibit B

This 2001 NB had suspension grip it couldn’t exploit. Over iced coffee a parts list was sketched: Carrillo A-beam rods, Wiseco 84 mm pistons (9.5:1), ACL race bearings, ARP studs, and Supertech springs. After a one-day tear-down, machine shop spent four weeks and $1,117 on a 0.5-mm overbore, decking, line-hone, full valve job, and balance. We then rented a chilled clean-room for $138 and burned

five vacation days assembling the short-block with Boundary billet oil-pump gears and an ATI damper. Back in the bay, a trusted tuner coaxed 208 whp at 10 psi via a ME221 ECU, the dyno and tuning bill adding $430. Totals landed at $2,921 in parts, plus roughly $1,375 for machining, fluids, and consumables, and about sixty blended labor hours. Ten weeks from first wrench to first boost, the car idles like stock yet screams to 7,600 rpm, until we decide the boost knob needs another twist.

Exhibit C

Some owners skip the smell of assembly lube and want a turnkey monster with dyno sheets to prove it. This Renzo-Spec build begins with a $344 planning retainer and a fifteen-page proposal. The parts cart hit $6,529: Molnar H-beams,

custom 11:1 CP pistons, billet main caps, ATI damper, Fluidyne radiator, CAT cams with Kelford springs, +1 mm Inconel valves, and a Haltech Elite 1500 ECU. Five weeks of machine work produced an align-bored, torque-plate-honed, O-ringed block, ported head, and cryo-treated crank. Two dry builds verified every clearance before the final assembly invoice of $2,062 (fifty shop hours). Dyno and track validation tacked on $601 but returned 372 whp on E50 through six flawless twenty-minute sessions, never topping 103 °C oil temp.

Common Pitfalls & Solutions

Machine-shop lead time came first; each builder demanded a promised-ready date in writing, yet only Renzo-Spec nailed it. Skipping measurements can grenade an engine before it fires, plastigauge saves crank when a big-end proved tight. Shipping charges become budget vampires unless you batch orders, trimming freight by 40 percent. Every diary upgraded oil-pump internals, cheap insurance against the BP engine’s pressure gremlins. Finally, scope creep ruins budgets; Renzo-Spec froze specs once deposits cleared, preventing impulse upgrades from derailing the schedule.

Budget Optimizers If You Haven’t Started Yet

Buy a spare BP core first so you can keep driving while the rebuild happens and avoid emergency-engine panic buys. When you do hit the machine shop, bundle operations, having the block align-bored and honed in one setup saves both accuracy and pesos. If you go the pro-builder route, lean on their distributor accounts for a quiet five-to-ten-percent parts discount. Most importantly, decide on your ECU and fueling strategy at the outset; nothing hurts more than paying for dyno time twice because you changed your mind after the first tune.

Ask yourself which you value more: the zen of turning wrenches or the thrill of turning laps. A methodical stock refresh teaches nearly everything about engine building at a fraction of the cost. Forged street builds, strike a delicious balance between civility and shove. Full-race motors are love letters to speed and will happily devour your wallet, weekends, and maybe your sanity, yet the grin at 7 500 rpm on corner exit is hard to beat. Whatever chapter you choose, document every step: photos, torque sheets, and yes, even the receipts that make you wince. Your personal engine-rebuild diary might just save the next Miata fan a fortune, or inspire them to yank out a perfectly good roadster heart and start writing their own story.